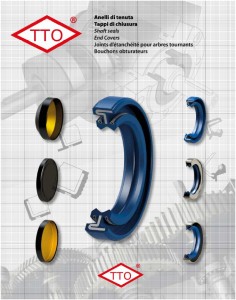

Oil seals

Oil seals are used to seal rotating elements, devices such as shafts, axles. Prevent leakage of lubricants and protect the equipment against foreign objects and other external elements. Selection of the appropriate forms and materials depends on the working conditions, the operating temperature, the rotational speed of the shaft and pressure.

Oil seals are used in transmissions, washing machine, gearboxes, motors and other applications. Purpose of use is defined primarily in terms of protection offered by the seal.

The most common types of oil seals are:

- Typ SC – with one oil lip, the outside part of the seal is of rubber

- Typ TC – with additional dust lip, the outside part of the seal is of rubber

- Typ TB –with additional dust lip, the outside part of the seal is made of smooth metal ring, which is a finely milled, drawn or turned.

General standard materials

| DESCRIPTION | NBR70 Acrylonitrile rubber |

FKM70 Fluoroelastomer |

VMQ70 Silicone rubber |

| Max. working temperature °C | -20 ÷ +120 | -18 ÷ +220 | -50 ÷ +170 |

| Hardness Shore A (±5) | 70 | 75 | 70 |

| Specific gravity g/cm3 | 1,20 ÷ 1,26 | 2,12 ÷ 2,18 | 1,27 ÷ 1,33 |

| Max. working speed m/s | 12 | 40 | 25 |

Features and information materials on our website are exclusively general information purposes only and are not considered binding. The values to be used in specific cases may vary, depending on the raw materials used and work conditions.

Catalogs: